DOURRY INTELLIGENT

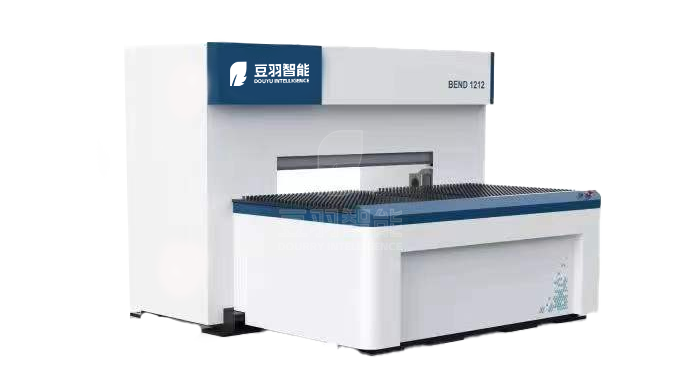

Intelligence Positive Bending Center

There are three specifications of Intelligence Positive Bending Center, 1.2 meters, 1.5 meters and 2 meters. It uses a human-machine interface (HMI) for operation, which can display and set various data, monitor the operating status of the machine, and has automatic alarm and fault self-diagnosis functions. Ergonomic design, simple operation, easy to understand programming, and quick to get started. Through careful and clever design, the bending tool can perfectly avoid the pressure package on the door panel. Multiple working modes can be selected independently, providing high flexibility. When an operation fault occurs, the system will promptly alarm and display the fault location and fault code to facilitate technicians to quickly judge and eliminate. Using sensors as detection components further ensures the processing accuracy of the workpiece.

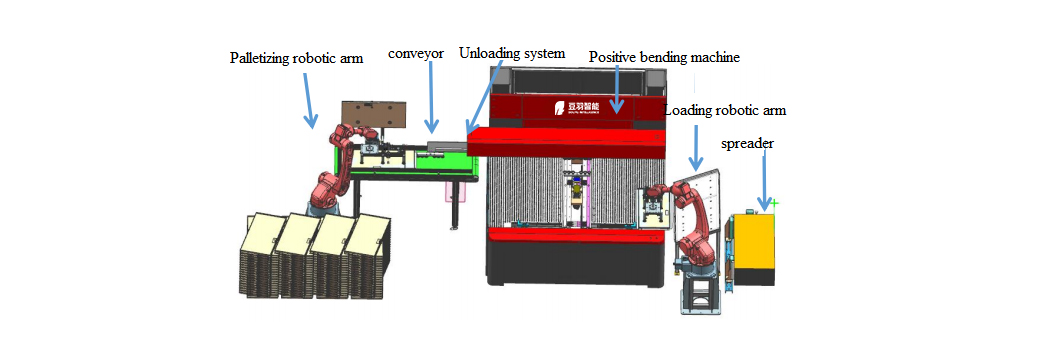

WORKING FLOW:

{{ flow }}

Characters

- {{ value }}

Heavy Duty Hydraulic Decoiler

- Applicable materials: cold rolled plate, standard plate, stainless steel

- Material width: 1250mm/1500mm

- Inner diameter of coil: φ480-530mm

- Coil outer diameter: φ1320 mm

High Precision Leveling Device

- It adopts 17 pieces rollers driven by servo motor and gear box.

- No. of rollers: 17 pieces 8 upper rollers and 9 down rollers

- Material of rollers: Alloy steel with quenched and tempered processing and hard chromium plating

- Leveling accuracy: ≤1.5mm/

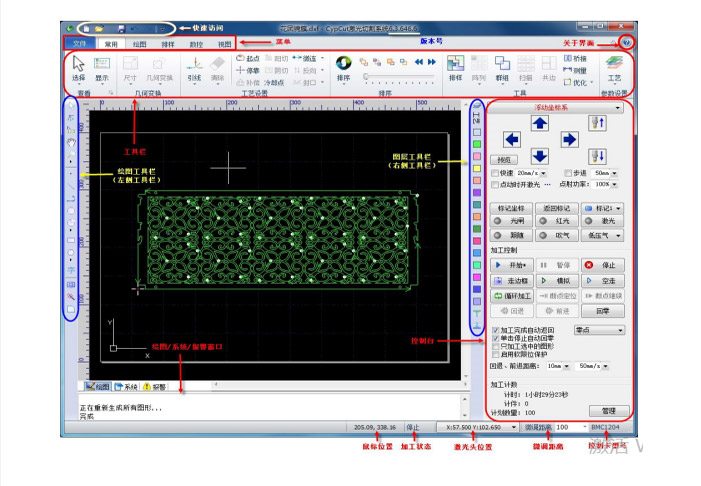

Opeerating system

Cyp Cut controlling system is a set of software for plane laser cutting, including laser cutting process processing, common layout functions and laser processing control. The main functions include graphics processing, parameter setting, custom cutting process editing, layout, path planning, simulation, and cutting process control. CypCut can also be installed on a separate laptop for pre-processing design.

SPECIFICATION

| Model | DBC1200 | DBC1500 | DBC2000 | |

|---|---|---|---|---|

| Material length (min. to max.) | 240-1200mm | 240-1500mm | 240-2000mm | |

| Material width (min. to max.) | 240-550mm | 240-550mm | 240-550mm | |

| Maximum bending height | 40mm | 40mm | 40mm | |

| Maximum bending speed (s/knife) | 0.3s/c | 0.3s/c | 0.3s/c | |

| Work surface height | 850mm | 850mm | 850mm | |

| Conventional bending platethickness | Cold plate 410N/mm | 0.4-0.7mm | 0.4-0.7mm | 0.4-0.7mm |

| Angle deviation (full length) | ±40' | ±40' | ±40' | |

| Straightness and Parallelism | 0.6mm | 0.6mm | 0.6mm | |

| Bending plate shape tolerance | ±0.2mm | ±0.2mm | ±0.2mm | |

| Bending outer R and plate thickness t multiple | 1.5-2mm | 1.5-2mm | 1.5-2mm | |

| Minimum height ofbending plate | 5 times the plate thickness | |||

| Power supply capacity, three phase four-wire 380v | 70kVA | 70kVA | 70kVA | |

| Gas consumption | 5l/min | |||

| Air pressure | 0.6MPa | |||

| Dimensions | 2200*2560*1800mm | 2500*2560*1800mm | 3000*2560*1800mm | |

Notice:

1. Any change technical data shall not be advised additionally.

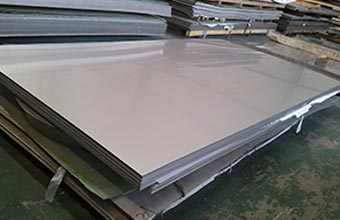

APPLICABLE RAW MATERIALS

aluminum plate, carbon steel plate, stainless steel plate, galvanized plate, yellow copper plate

-

Aluminum plate

-

Carbon steel plate

-

Yellow copper

-

Stainless steel

Physical drawing

-

Aluminum Curtain Wall

-

Ceiling Making

-

Elevator Making

-

Fire-Proof Door

-

Electric Box

-

Kitchen Equipment Making

Apply to more areas

Copyright © 2001-{{year}} HENAN DOURRY INTELLIGENT EQUIPMENT CO., LTD. All Rights Reserved.